Purified Terephthalic Acid (PTA) is a key chemical compound primarily used in the production of polyester fibers, resins, and films. It is a white, crystalline powder with excellent chemical stability and is produced through the oxidation of para-xylene, typically using acetic acid as a solvent and a catalyst like cobalt-manganese or cobalt-bromine. Here’s a breakdown of its definition, applications, and some statistics:

PTA Process Optimization for IOCL Panipat

Definition:

Purified Terephthalic Acid (PTA) is an organic compound with the chemical formula C₆H₄(COOH)₂. It belongs to the family of aromatic dicarboxylic acids and is derived from the oxidation of para-xylene.

Applications:

- Polyester Production

- Engineering Plastics

- Coatings and Adhesives

- PET Film

- Other Applications

Summary:

Axis Solution, serving as an Integrated Solution Provider, collaborated with the esteemed Indian Oil Corporation Limited (IOCL) Panipat Plant to optimize and enhance the Purified Terephthalic Acid (PTA) application process.

Collaboration Overview:

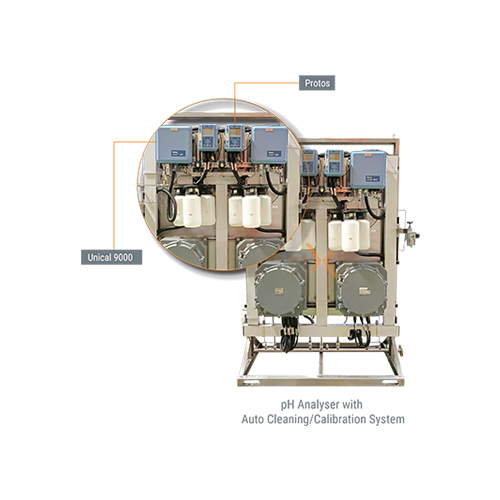

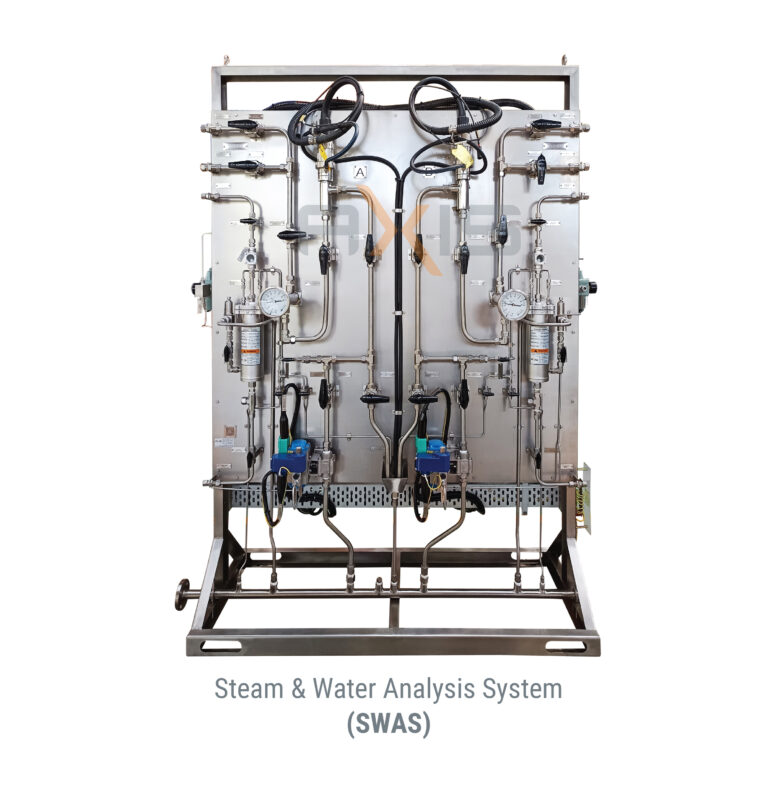

Axis Solution partnered with Indian Oil Corporation Limited (IOCL) Panipat Plant to provide integrated solutions for the PTA application process for pH measurement. Leveraging expertise in process optimization and cutting-edge technology, Axis Solution aimed to enhance operational efficiency, productivity, and product quality at the Panipat Plant.

Challenges Faced & Problem Identified:

- Life of pH sensor: Process’s Aggressive Media & dusty environment erode pH sensor and diminish the life span of it. In most of Textile & Polyester application, it’s highly difficult to clean the pH probe in process line on regular interval without interrupting the process.

- Reading Accuracy: For accurate reading, pH sensor must be clean multiple times during the regular interval during process or every day. In addition to it, calibration is required multiple times without disrupting the process.

- Maintenance: Keeping pH sensors operational in textile and polyester manufacturing settings without halting the process is a daunting challenge for workers. It demands precise training, adherence to safety protocols, and careful execution to ensure that necessary actions such as manual removal, cleaning, and calibration are performed without compromise.

Key Solutions Provided:

- Advanced Process Control Systems: Axis Solution implemented state-of-the-art control systems to optimize process parameters and maintain product consistency and quality.

- Energy Management Solutions: The collaboration introduced energy-efficient technologies and practices to reduce power consumption and enhance sustainability.

- Quality Assurance Systems: Axis Solution deployed quality assurance systems and protocols to ensure the production of high-quality PTA meeting stringent industry standards.

- Training and Support: Axis Solution provided comprehensive training and support to the plant personnel to ensure smooth implementation and operation of the integrated solutions.

Results and Benefits:

- Increased Productivity: The collaboration led to increased production capacity and throughput, enabling IOCL Panipat Plant to meet growing market demand for PTA.

- Improved Quality: Axis Solution’s integrated solutions resulted in improved product quality, reducing defects and customer complaints.

- Cost Savings: By optimizing resource utilization and reducing waste, the project contributed to significant cost savings for the Panipat Plant.

- Enhanced Competitiveness: The collaboration strengthened IOCL’s competitive position in the PTA market by enhancing operational efficiency and product quality.

Conclusion:

As a result of this successful partnership, Axis Solution have not only achieved operational excellence but have also set a benchmark for collaboration and innovation in the petrochemical industry. Looking ahead, the lessons learned and the outcomes achieved will serve as a foundation for future endeavors, driving continuous improvement and value creation for all stakeholders involved.