Advanced Analysis Techniques for Detecting Hydrocarbons in Water

Introduction:

Hydrocarbons (HC) in water pose significant challenges in the oil refinery industry, where steam is a critical utility used across various processes. In refining, steam plays a vital role in fractionating towers, steam-cracking processes, and steam reforming. It’s also extensively used in heat exchangers to provide thermal energy. However, steam distillation is complex, given the numerous variables and the diverse compounds in crude oil. As steam condenses, the resulting condensate is fed into cooling circuits or waste heat recovery boilers (WHRB). Both systems often experience leaks, introducing hydrocarbons into the condensate or cooling water.

Challenges of Hydrocarbon Contamination

Detecting hydrocarbons in water, particularly in trace amounts (down to 5 ppm or less), is essential. The presence of organic compounds in boiler systems can lead to various issues. Under high temperature and pressure, these compounds break down into harmful substances like ammonia, CO2, and various acids, including hydrochloric and sulfuric acids. These breakdown products can significantly impact low-pressure turbine blades and increase iron corrosion rates in condensers. Thus, detecting and mitigating hydrocarbon contamination is critical to maintaining system integrity and performance.

Current Detection Methods

One common method for detecting hydrocarbons in water is measuring Total Organic Carbon (TOC) using the UV per sulphate method. This involves treating the sample with sodium per sulphate and phosphoric acid, converting inorganic carbon compounds to CO2, and measuring the resultant CO2 with infrared (IR) detection. However, this method has several limitations, including the complexity of the process, hazardous reagent handling, frequent maintenance of peristaltic pumps, and a time-consuming cyclic process with mandatory wash cycles.

Alternative Detection Solutions

Different solutions exist based on the solubility of hydrocarbons in water. Soluble hydrocarbons, like small, nonpolar molecules, pose detection challenges. Conversely, insoluble hydrocarbons tend to float on the water surface as oil slicks.

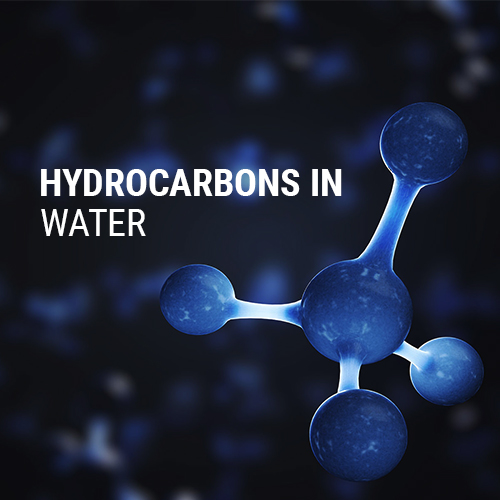

Oil in Water Analyzers Using UV Fluorescence:

- UV fluorescence is effective for detecting oil in water. When a molecule absorbs UV light and re-emits it at a longer wavelength, fluorescence occurs.

- Typical components include a UV source (often a xenon lamp), a fibre optic probe, and photomultiplier tubes (PMT). The system uses excitation and emission filters to select appropriate wavelengths and measure fluorescence intensity, correlating it to hydrocarbon concentration.

- This method offers rapid response times, reagent-less operation, minimal calibration drift, and high reliability with no moving parts.

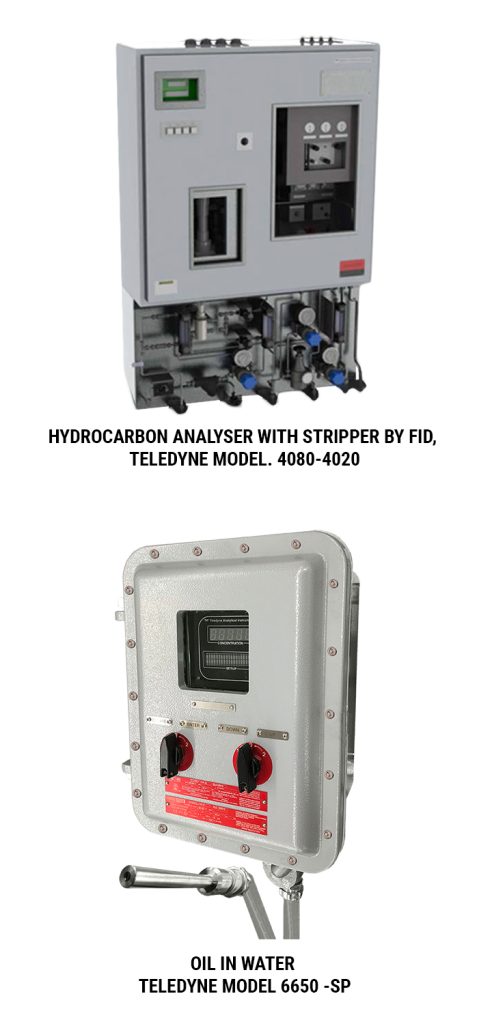

Hydrocarbon Detection with Strippers and Flame Ionization Detectors (FID):

- For hydrocarbons soluble in water, stripping involves removing HC from water and analysing it with an FID.

- This system includes a temperature-controlled stripper with nitrogen cross-flow, a sample drier, and an FID. The stripped hydrocarbons are fed to the FID, providing quick and accurate readings.

Benefits include direct hydrocarbon measurement, reagent-less operation, rapid analysis, and maintenance-free design.

Conclusion

Effective detection of hydrocarbons in water is crucial for maintaining refinery operations and preventing equipment damage. By leveraging advanced technologies like UV fluorescence and FID-based strippers, refineries can achieve accurate, rapid, and reliable hydrocarbon detection. For more information on tailored solutions for hydrocarbon detection, contact AXIS SOLUTIONS at info@axisindia.in.