Sensing, Signal Transmission and Signal processing is the basic flow pattern for measuring Parameters. Sensor, Cable & Transmitters are the main assembly parts of this system.

Over the years, many revolutionary technologies has been adapted to get highly accurate & most precise measuring though still we have many challenges which distort the final measuring value.

When it comes to Liquid Analysis, which places massive demand on sensor and on the transmission of measured value from the sensor to transmitter. Moisture, Harsh environment like dirt, corrosion, salt bridge, over pressure and interference potentials are the challenges.

In addition, when it comes to pH measurement, low measuring signals and very high sensor internal resistances require a high-impedance connection to the transmitter. The measured value being altered or even caused the complete failure of the measurement with the presence of moisture in conventional, analog connector systems. Field calibration is the main challenge for the contact type sensors plus there is no process to diagnose disturbed signal transmission.

Memosens: Contactless, Digital, Innovative

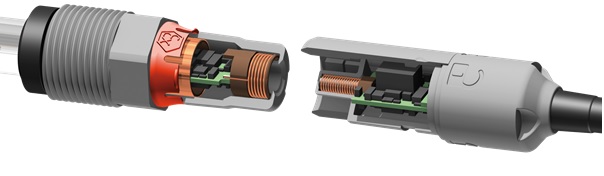

What’s special about Memosens? The measuring signals are digitalized at sensor head and transferred inductively (contactless). As a result of contactless bi-directional signal transmission, the inductive coupling also provides the power supply to the sensor.

Memosens: Simple, Waterproof, Cost-efficient

The Memosens plug & play system is 100% waterproof and resistant to dirt, corrosion, salt bridges, over pressure and interference potentials. The robust Memosens connection also means high resistance to mechanical influences. Even cable lengths of 100 m function perfectly for applications with Memosens technology.

Its inductive signal transmission results in perfect galvanic isolation. Precise measurements are possible even with difficult potentials. Further measures for equipotential bonding such as solution ground are unnecessary.

Memosens sensors are available for pH, ORP, conductivity and oxygen parameters.

On-site sensor exchange using pre-calibrated sensors reduces process downtime and regular regeneration extends sensor lifetime. Qualified personnel can pre-calibrate Memosens sensors in the laboratory that benefits users with increased quality of the calibration and measurement precision in turn. Memosens prevents expensive process downtime during sensor replacement due to very short maintenance times.

Memosens: Data Management, Predictive Maintenance

Predictive Maintenance – Reliable process management with intelligent diagnostics functions such as conditions of use, sensor wear, operating time and a CIP/SIP or autoclaving counter ensure greater safety, effectiveness and reliability. A load matrix evaluates the individual wear data of the sensors and the adaptive calibration timer calculates the optimal process-dependent maintenance cycle.

Memosens 2.0 stores 8 times more data, such as calibration histories and load matrices, paving the way for true predictive maintenance and enhanced IIoT services. It also offers full flexibility in hazardous areas since all Ex sensors can be matched to all Liquiline transmitters with the respective approval. Memosens 2.0 sensors are backwards-compatible for fast integration into existing systems.

Overall Advantages of Memosens

Non-contact digital transmission

- corrosion-free

- A coupling system that can even be connected under water

- No leaks, No measured value distortion (due to moisture), No corrosion (salt bridges)

EMC safety

- Perfect galvanic isolation of medium and transmitter

- Independent of “symmetrically high-resistance“, “asymmetrical“ or impedance converter

Easy calibration

- Easy replacement of sensor with laboratory calibrated sensors

- No inaccurate field calibrations due to poor weather conditions

- Up to 40% longer service life of sensor thanks to regular regeneration

Data management

- Complete life cycle documentation

- Calibration history traceability

- Recording of sensor load data (total operating hours, operating hours under extreme process conditions, etc.)

- Export of data to html, MS Excel®

Correct measured values

- Active display of disruptions to the connection between sensor and transmitter

- Hermetically sealed sensor plug-in head is overpressure safe and submersible

In built Memory

- Predictive maintenance possible (storage of calibration and operating data)

- Easy sensor replacement with automatic sensor recognition

Memosens technology is benefiting industries like chemical, pharmaceutical, food & beverages, water, oil & Gas, waste management, fertilizer, power generation, cosmetic all around the world by providing accurate and reliable data.

In process analytics, for 75 years Knick is one of the leading supplier of analog and digital sensors for measuring pH, ORP, conductivity and oxygen, Knick also offers high-quality industrial measuring instruments and fittings. Knick systems for automatic cleaning and calibration are unique solutions on the market.

Axis Solutions Pvt Ltd is the Authorized representative and distributor for the India region. Our product expert can advise and support on process analytics application. You can check the case study on our “what’s new” Website tab

Ref. Links