Revolutionizing Industrial Efficiency: A Global Perspective on SWAS

The Invention and History of SWAS

Steam and Water Analysis Systems (SWAS) serve as the silent champions of contemporary industries. These advanced systems carefully oversee the quality of boiler feed water and steam, safeguarding optimal plant efficiency, averting expensive equipment breakdowns, and reducing environmental impact.

A Global Perspective on SWAS

The demand for SWAS is surging globally as industries across the world strive for greater efficiency, reduced downtime, and enhanced product quality. From the bustling manufacturing hubs of Asia to the energy-efficient power plants of Europe, SWAS systems are playing a critical role in driving industrial progress.

The Evolving Landscape of SWAS

The SWAS industry is undergoing a significant technological transformation, driven by factors like:

- Digitalization: Integrating SWAS systems with IoT and cloud computing enables remote monitoring, predictive maintenance, and data-driven decision-making.

- Artificial Intelligence: AI-powered analytics can optimize system performance, identify anomalies, and predict potential failures.

- Advanced Sensors: The development of more accurate and reliable sensors enhances the precision of water and steam quality measurements.

- Miniaturization: Smaller, more compact SWAS components enable easier installation and maintenance.

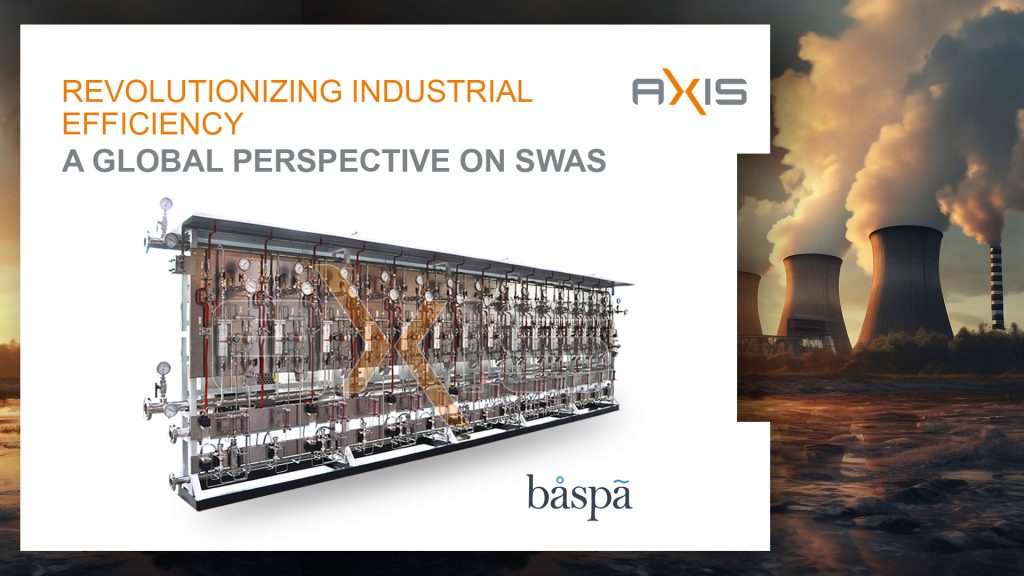

Axis SWAS: A Local Solution with a Global Impact

Axis Solutions, a leading provider of SWAS Products and solutions, is at the forefront of this technological revolution. With a strong local presence and a global outlook, Axis offers a comprehensive range of SWAS solutions that deliver exceptional performance and value.

Key Benefits of Axis SWAS:

- Precision and Accuracy: State-of-the-art sensors and advanced algorithms ensure accurate measurement of critical parameters.

- Real-time Monitoring: Instantaneous data insights enable proactive maintenance and optimization.

- Enhanced Efficiency: Optimized boiler operation reduces energy consumption and operational costs.

- Improved Product Quality: Consistent steam quality leads to less maintenance and longer life due to reduced defects.

- Regulatory Compliance: Adherence to stringent environmental and safety regulations.

- Remote Monitoring and Control: Remote access and control for enhanced operational efficiency.

- Predictive Maintenance: Anticipates potential issues, minimizing downtime.

In addition to these benefits, Axis Solutions provides heat load calculation for the SWAS System, leveraging advanced technologies to deliver near-saturated steam parameter status. This capability exceeds industry expectations, ensuring unparalleled performance and precision. By achieving near-saturated steam conditions, our SWAS Systems enhance operational reliability, optimize process efficiency, and deliver a competitive edge in demanding industrial environments.

A Glimpse into the Future of SWAS

The future of SWAS is bright, with exciting advancements on the horizon:

- IoT Integration: Seamless integration with IoT devices for real-time data collection and analysis.

- Cloud-Based Solutions: Enhanced data security, remote access, and collaborative capabilities.

- Advanced Analytics: Data-driven insights to improve decision-making and optimize processes.

Conclusion

SWAS systems are the silent guardians of industrial efficiency, ensuring optimal performance, reduced costs, and minimized environmental impact. As technology continues to evolve, Axis Solutions remains committed to delivering innovative and reliable SWAS solutions that empower industries worldwide to thrive in the future.