22-26 February 2025 | India Expo Mart, Greater Noida, NCR Delhi.

22-26 February 2025 | India Expo Mart, Greater Noida, NCR Delhi.

06-08 March 2025 | New Exhibition Hall, Chennai Trade Centre, Chennai.

7 & 8 February 2025 | CIDCO Exhibition & Convention Centre, Vashi, Navi Mumbai.

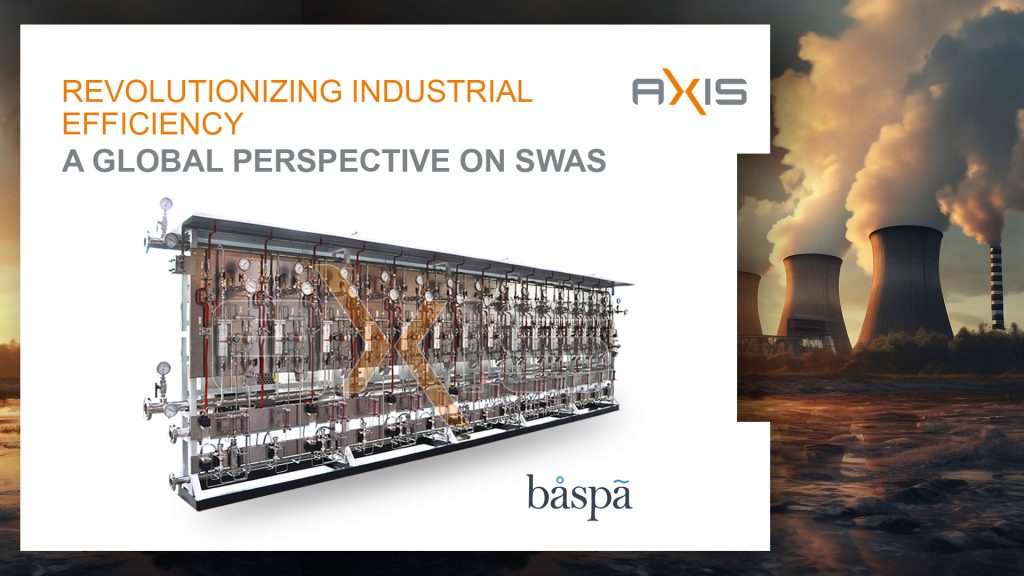

Revolutionizing Industrial Efficiency: A Global Perspective on SWAS

Steam and Water Analysis Systems (SWAS) serve as the silent champions of contemporary industries. These advanced systems carefully oversee the quality of boiler feed water and steam, safeguarding optimal plant efficiency, averting expensive equipment breakdowns, and reducing environmental impact.

The demand for SWAS is surging globally as industries across the world strive for greater efficiency, reduced downtime, and enhanced product quality. From the bustling manufacturing hubs of Asia to the energy-efficient power plants of Europe, SWAS systems are playing a critical role in driving industrial progress.

The SWAS industry is undergoing a significant technological transformation, driven by factors like:

Axis Solutions, a leading provider of SWAS Products and solutions, is at the forefront of this technological revolution. With a strong local presence and a global outlook, Axis offers a comprehensive range of SWAS solutions that deliver exceptional performance and value.

In addition to these benefits, Axis Solutions provides heat load calculation for the SWAS System, leveraging advanced technologies to deliver near-saturated steam parameter status. This capability exceeds industry expectations, ensuring unparalleled performance and precision. By achieving near-saturated steam conditions, our SWAS Systems enhance operational reliability, optimize process efficiency, and deliver a competitive edge in demanding industrial environments.

The future of SWAS is bright, with exciting advancements on the horizon:

SWAS systems are the silent guardians of industrial efficiency, ensuring optimal performance, reduced costs, and minimized environmental impact. As technology continues to evolve, Axis Solutions remains committed to delivering innovative and reliable SWAS solutions that empower industries worldwide to thrive in the future.

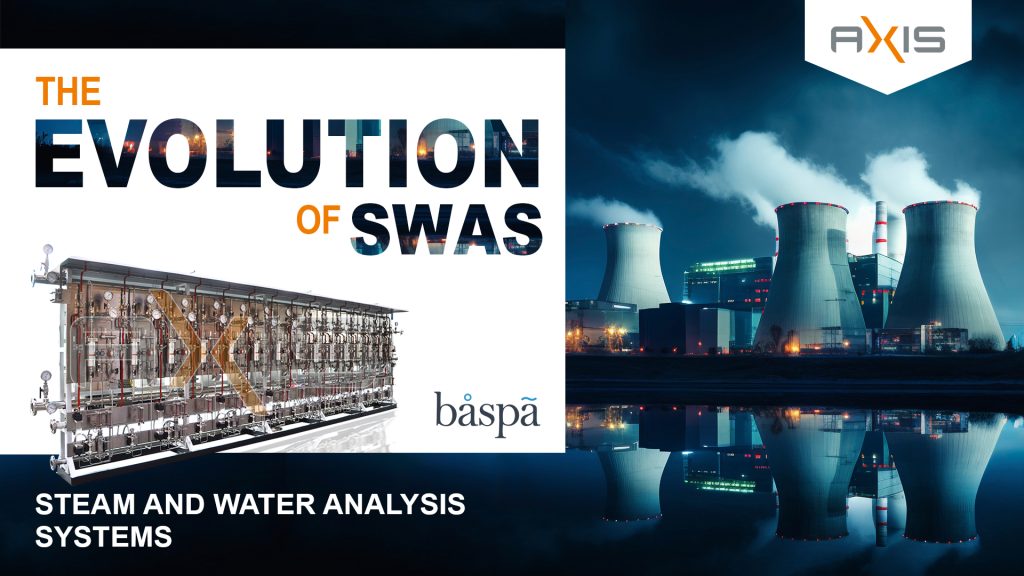

The

Evolution of Steam and Water Analysis Systems (SWAS)

Steam and Water Analysis Systems (SWAS) originated in the early 20th century with the rise of industrial steam-powered turbines and boilers. While no single individual is credited as the inventor of SWAS, Dr. Vernon L. Anderson, a pioneer in steam turbine chemistry, laid foundational principles that shaped the development of SWAS. Early systems were rudimentary, aimed at monitoring pH, conductivity, and dissolved oxygen to prevent damage to turbines and boilers. Companies like Siemens and General Electric furthered this innovation, making SWAS an indispensable package of power plant infrastructure.

The need for SWAS became apparent as industry trends began using low-pressure to super-critical boilers, where even minor impurities in water or steam could lead to catastrophic failures. Impurities such as pH, conductivity, and dissolved oxygen, silica, salts, nitrates and many other dissolved gases cause scaling, corrosion, and deposition in boilers and turbines, reducing efficiency and lifespan. To mitigate these risks and improve operational reliability, SWAS systems were developed to monitor water and steam chemistry continuously. This ensured that power plants could operate safely and efficiently, minimizing downtime and maintenance costs.

Globally, the first large-scale implementation of SWAS was undertaken by Westinghouse and Alstom in the 1950s in thermal power plants in the United States and Europe. In India, Bharat Heavy Electricals Limited (BHEL) introduced SWAS during the 1970s as part of their power plant projects. NTPC, India’s largest energy conglomerate, was one of the earliest adopters of SWAS systems to ensure the reliability of its thermal power stations. These systems marked the beginning of a structured approach to steam and water quality monitoring in the Indian power sector.

In India, SWAS has become a critical technology across multiple sectors, using boiler as an equipment. Market is demanding advance SWAS systems that are equipped with advanced sensors, IoT capabilities, and real-time data diagnostics, ensuring precise monitoring, control and remote maintenance. With increasing emphasis on sustainability and efficiency, Indian industries are focusing on adopting SWAS systems that not only ensure compliance with environmental regulations but also optimize resource. Government initiatives like “Make in India” have further driven the growth of indigenous SWAS manufacturing, contributing to the nation’s industrial development at a competitive price.

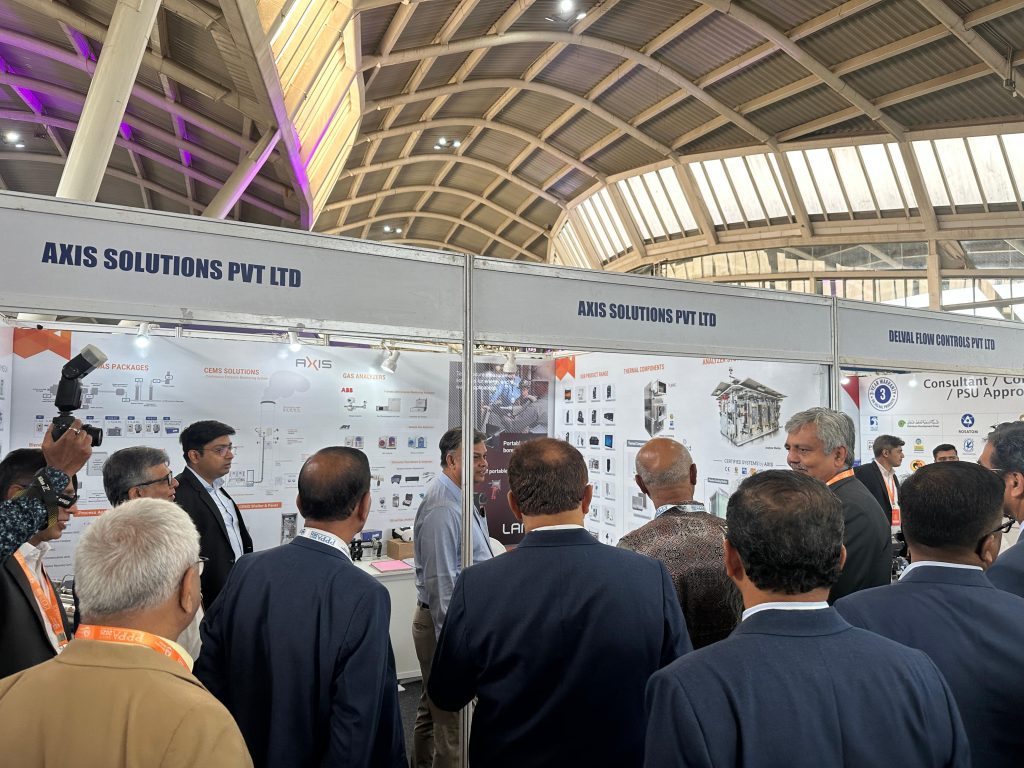

For over two and a half decades, Axis Solutions has been at the forefront of engineering excellence, specializing in SWAS technology. As a market leader, Axis manufactures essential “Baspa” components and integrates comprehensive SWAS systems tailored to the rigorous needs of industries like power generation, petrochemicals, and pharmaceuticals. Leveraging in-house manufacturing capabilities and a commitment to innovation, Axis offers state-of-the-art SWAS systems that deliver precise and dependable performance, even in the most challenging environments.

Axis SWAS systems deliver exceptional precision, durability, and ease of operation and maintenance. They accurately track critical parameters such as pH, conductivity, silica, sodium, and dissolved oxygen. The modular design allows for flexible customization and scalability, ensuring compatibility with various applications. With a focus on energy efficiency and long-term reliability, Axis systems significantly reduce operational costs and environmental footprint. Real-time data monitoring and automated controls enhance operational safety and minimize the need for manual intervention.

Axis Solutions always differentiates itself through its customer-centric approach and technical innovation. Its SWAS systems is vertically integrated with State-of-the-art modern automation and control systems, offering predictive maintenance and advanced analytics. Axis leverages Industry 4.0 and cloud-based solutions, enabling clients to achieve higher operational efficiency and sustainability. With a legacy of trust and innovation, Axis Solutions empowers industries to stay competitive in a rapidly evolving industrial landscape.

Axis Solutions’ SWAS systems exemplify the perfect blend of engineering excellence and modern technology, making them most preferred partner for industries that are striving for efficiency, reliability, and sustainability.