Steam and Water Analysis System (SWAS)

Steam and Water Analysis System (SWAS)

Introduction

Steam and Water Analysis System (SWAS) is an essential system used in various industries to monitor and control the quality of steam and water used in various processes. SWAS is a complete analytical system that is designed to measure and analyze the quality of steam and water at various stages of the process. It consists of several analytical instruments such as conductivity meters, pH meters, dissolved oxygen analyzers, and silica analyzers.

Steam can be as hot as 560°C. Pressures can be as high as 250 bar. Samples are at high temperature & pressure. Sample conditioning is required to bring down the temperature & pressure at the desired level. To keep the power plant up and running with minimum erosion and corrosion of the steam turbine, steam boiler, and condenser, SWAS provides exact, precise measurements on all these critical parameters.

SWAS is widely used in industries such as power generation, chemical and petrochemical, pharmaceutical, and food and beverage. The main purpose of using SWAS is to ensure that the quality of steam and water used in the process is within the required parameters. Poor quality steam and water can lead to corrosion, scaling, and other problems that can affect the efficiency of the process and cause equipment failure.

Major Critical Parameters

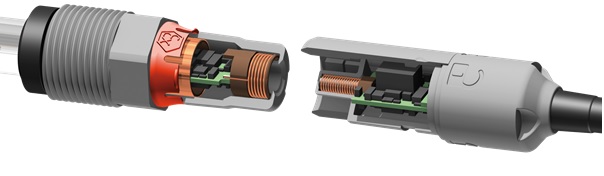

One of the key components of SWAS is the Conductivity meter. It measures the conductivity of water and steam, which is an indication of the total dissolved solids (TDS) in the sample. The TDS level in the water and steam is a critical parameter that needs to be monitored to ensure that it is within the required limits. High levels of TDS can lead to scaling and corrosion, which can cause damage to the equipment and reduce the efficiency of the process.

Another critical parameter that needs to be monitored is the pH level. The pH level of water and steam is an indication of its acidity or alkalinity. The pH level needs to be within the required range to prevent corrosion and scaling. The dissolved oxygen analyzer is another critical instrument used in SWAS. It measures the level of dissolved oxygen in water and steam. High levels of dissolved oxygen can cause corrosion, which can lead to equipment failure.

The Silica analyzer is another essential instrument used in SWAS. It measures the level of silica in water and steam. Silica can cause scaling, which can lead to reduced efficiency and equipment failure. The presence of silica can also cause problems in the treatment of wastewater.

SWAS have mainly two parts of system, Wet Panel and Dry Panel. In Wet Panel, Samples coming from different points are fed to this panel and it has contain all the components like Thermal auto shutoff valves (TSV), Pressure regulation valves (PRVs), Back pressure regulators (BPR) , gauges that indicates pressure and temperature, Sample coolers and sensors in many cases. In Dry Panel, Indicators, analyzers, Transmitters, remote signaling, interconnection to control room and DCS systems.

Get the best of SWAS

Axis Solutions Private Limited, India utilize modern technologies and proven techniques to manufacture and integrate excellent Steam and Water Analysis System (SWAS). We are leading manufacturer and solutions provider of SWAS systems for critical parameters such as pH, Conductivity, Dissolved Oxygen, Silica, Sodium, Hydrazine and Phosphate etc. With expertise in sample cooler designs, Automatic High Temperature mechanical thermal shut-off valve and Effective Temperature & Pressure reduction with constant flow regulation to improve analyzer safety and reliability, we, axis solutions is the leading supplier of SWAS components and System integrator of single stream to multiple stream SWAS packages. We have space saving SWAS designs as well for compact spaces.

Axis Solutions Private Limited, India utilize modern technologies and proven techniques to manufacture and integrate excellent Steam and Water Analysis System (SWAS). We are leading manufacturer and solutions provider of SWAS systems for critical parameters such as pH, Conductivity, Dissolved Oxygen, Silica, Sodium, Hydrazine and Phosphate etc. With expertise in sample cooler designs, Automatic High Temperature mechanical thermal shut-off valve and Effective Temperature & Pressure reduction with constant flow regulation to improve analyzer safety and reliability, we, axis solutions is the leading supplier of SWAS components and System integrator of single stream to multiple stream SWAS packages. We have space saving SWAS designs as well for compact spaces.

In conclusion, SWAS is a critical system used in many industries to monitor and control the quality of steam and water used in various processes. It consists of several analytical instruments such as conductivity meters, pH meters, dissolved oxygen analyzers, and silica analyzers. The proper use of SWAS can help to prevent corrosion, scaling, and other problems that can affect the efficiency of the process and cause equipment failure.