Safe, Accurate, Efficient: Axis & Panametrics Driving Green Hydrogen Excellence

A Gujarat-based clean energy solutions leader is establishing an electrolyzer-driven green hydrogen plant in India, which required a highly accurate and dependable analyzer system. The system needed to measure trace concentrations—0.8% hydrogen (H₂) in oxygen (O₂) streams and 0.2% oxygen (O₂) in hydrogen (H₂) streams—parameters critical for ensuring safety, purity, and efficiency in hydrogen production and handling.

Axis, is the 360° Panametrics System Integrator (SI) for India, partnered with Panametrics to design and deliver a comprehensive analyzer system integrated with a custom-built Sample Handling System (SHS). The solution was engineered to meet the client’s stringent requirements, including Zone-2 hazardous area compliance, repeatability of less than 1 ppm, high measurement accuracy, and a robust design capable of operating at 30 barg pressure and 65°C temperature.

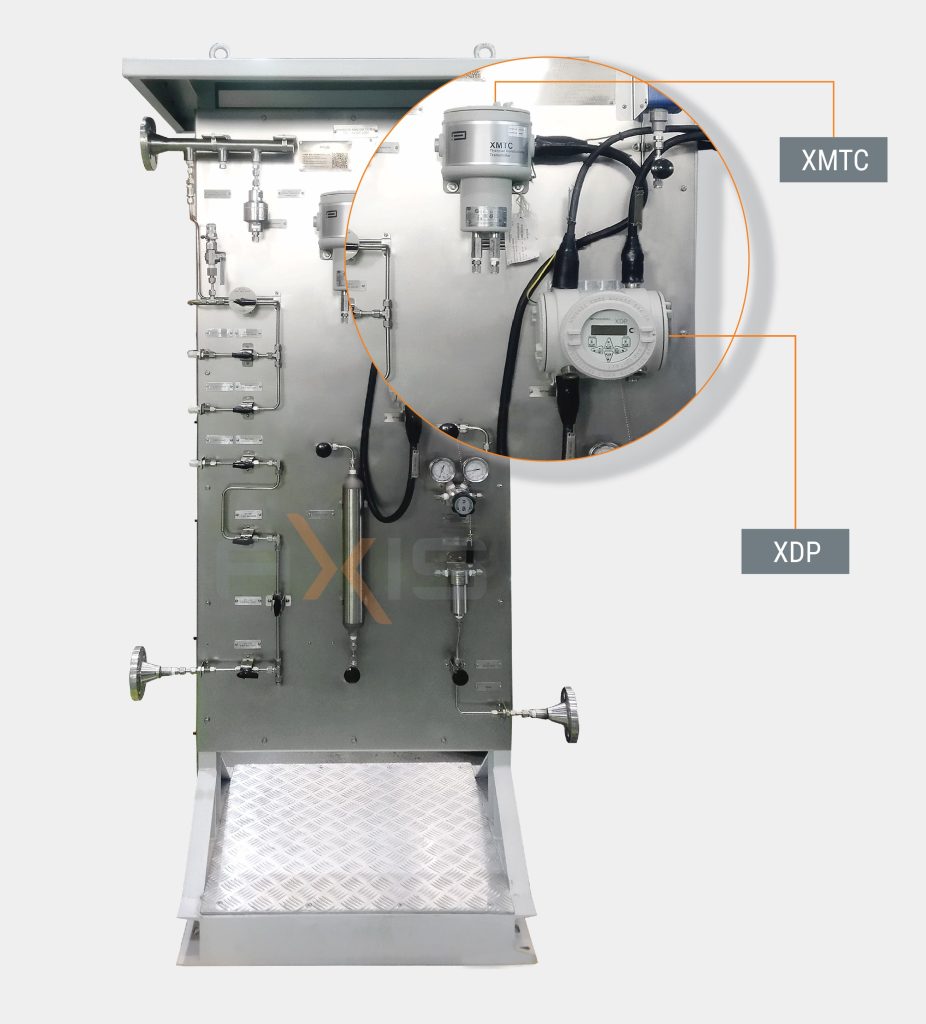

Panametrics, with over six decades of expertise in gas analysis, delivers reliable, safe, and efficient measurement solutions tailored for green hydrogen projects. Its proven instruments such as the Oxy.IQ, XMTC, and moisture analysis systems ensure product purity, improve electrolyzer performance, and maintain safety in hazardous environments. Backed by low-maintenance technology and smart control features, Panametrics stands as a trusted partner for scaling green hydrogen production.

Panametrics’ Key USPs for Green Hydrogen :

- Proven Expertse: 60+ years of experience in hydrogen applications, including electrolyzer integration.

- Complete Portfolio: Oxy.IQ for oxygen and XMTC for hydrogen purity,

- Safety & Reliability: Hazardous-area certified; XMTC is SIL-rated for critical safety applications.

- Low Maintenance: Solid-state sensor design minimizes downtime and operational costs.

- Easy Integration & Control: XDP controller streamlines setup, provides local power, and supports automated calibration.

Final Thoughts & Attainments:

Using ultrasonic flow meters for LD gas flow measurement enhances plant safety, improves energy efficiency, reduces emissions, and ensures compliance with regulatory standards. These meters are highly reliable, low-maintenance, and provide precise measurement even under harsh conditions, making them an ideal choice for modern steel plants.

Key Product Benefits for Green Hydrogen Projects

- Purity Monitoring: Oxy.IQ tracks trace oxygen, ensuring hydrogen purity for fuel cell applications.

- Process Safety: XMTC provides continuous monitoring of high-concentration hydrogen for safe operation and leak detection.

- Hazardous-Area Ready: XDP is explosion-proof and features a magnetic keypad for safe, non-intrusive use.

- Low Maintenance: Solid-state sensors minimize downtime and operational costs.

- Integrated Control: XDP offers centralized display, local power, and automated calibration, simplifying system setup.

Axis’ Engineering Contributions

- Helium leak-tested tubing for zero leakage integrity.

- Nitrogen purging for safe operation and maintenance.

- Calibration gas setup for accuracy and repeatability.

- In-house vortex cooling products for high-temperature stability.

- Compliance to Hazardous Area Certification provided.

- SS316L analyzer body and sensor manifold for corrosion resistance and durability.

- Sample handling and routing manifolds were designed to enable simultaneous O₂ and H₂ analysis without interference, with independent isolation loops allowing maintenance without process shutdown

This deployment underscores Axis’ strength in delivering Make in India compliant engineered analyzer systems, aligned with global clean energy goals and hydrogen economy standards.

Problem Statement

Industry and Client Background

The client is a major energy and infrastructure solutions provider working in the domain of hydrogen generation via electrolysers. Their operations demanded ultra-reliable trace gas monitoring to ensure safe and efficient plant performance.

Specific Challenges Faced by the Client and its Resolutions.

- Requirement for trace-level measurement of H₂ in O₂ and O₂ in H₂.

- Hazardous area compliance (Zone-2, Group IIC, T3) for all equipment.

- Very high process reliability required at 30 barg operating pressure.

- A single cabinet was initially requested for both analysers, which posed safety, accessibility, and integration challenges.

- Resolution: Helium leak testing to ppm integrity levels.

- Resolution: Nitrogen purging of SHS before dispatch.

- Resolution: Provided dual cabinets with a safe and modular design approach.

Business and Technical Pain/Gain Points

- Compliance Solutions to cater Hazardous Area needs.

- Field Engineering and long-term support for plant operation with mandatory spares, operational spares, and commissioning spares.

- Ensure robust testing (FAT/SAT) to reduce commissioning delays.

- Span/zero calibration check

- Functional parameter verification

- Hydro/leak test with helium

- Response validation

- Power-on and operational checks

Critical Requirements and Constraints

- Accuracy: ±2% FS, Repeatability: <1 ppm.

- Response time: <10 sec for O₂, <3 sec for H₂ (90% response).

- System Cabinet with SHS Components and Gas Analyzers are of MS CRCA with FRP canopy as self-standing rack with Hazardous Approval.

- Continuous operation with calibration gases for 6 months post-SAT.

Results and Impact

- Delivered a precision analyser system meeting hazardous area compliance.

- Achieved fast response (<3 sec for H₂, <10 sec for O₂) ensuring real-time monitoring.

- Reduced downtime through inclusion of 2 years’ operational and mandatory spares.

- Enhanced client confidence with rigorous FAT & SAT protocols.

- Benchmarked a scalable solution for hydrogen economy projects under the Make in India framework.

Future Scope and Scalability

- Future integration with remote diagnostics and digital monitoring platforms.

- SHS design and analyser combination can be replicated for:

- Larger electrolyser capacities.

- Hydrogen fuel cell projects.

- Industrial gas monitoring in refineries and petrochemicals.

Conclusion

From trace-level accuracy to robust and reliable operation, this integrated solution demonstrates that safety, purity, and performance can seamlessly coexist. Partner with Axis to elevate your green hydrogen initiatives with confidence.