GAS FLOW METER - DigitalFlow™ XGM868i

The highly competitive Steel industry anticipates to grow at a steady and slow pace for several years, despite some residual overcapacity. However, the trend toward a circular economy aimed at continued use of resources and elimination of waste, along with enhanced Corporate Social Responsibility, may sustain the pace without a further economic contraction. The heavy industrial processes produced by steel mills, and metal heat treatment operations require multiple analysis points for process control and safety. They also use thousands of flow measurement points at their facilities and consume energy at a high rate.

AXIS provided Solution in steel industry LD Gas Flow Meter

The Steel industry faces a series of on-going challenges to manage and optimize its energy usage, efficiency and compliance, with growing stringent environmental regulations that require emissions monitoring to address climate change.

During the steelmaking process, molten iron is converted into steel by blowing oxygen into the iron to oxidize impurities. This reaction generates LD gas as a byproduct. This gas is rich in carbon monoxide (CO), carbon dioxide (CO₂), hydrogen (H₂), and other minor components. Accurate measurement of LD gas flow is critical for optimizing processes, ensuring safety, and enhancing energy efficiency

Challenge faced by client:

- To manage flow of LD Gas Client.

- Inconsistent measurement

- High maintenance needs

- Pressure drop

- Safety risks

- To protect reverse flow from CO gas holder to LD convertor was main challenge faced by client to avoid accident

Solution Provided by AXIS:

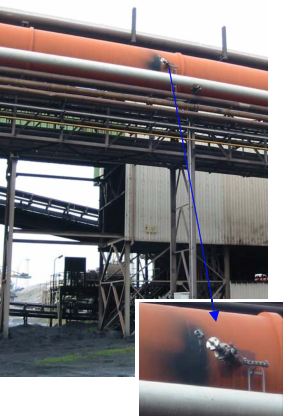

In response to client requirement Axis Solutions Limited supplied and installed Panametrics ultrasonic flow meter XGM868i to monitor flow of LD gas.

- Continuous monitoring of flow rates allows for immediate detection of any abnormal changes. Sudden drops or reversals in flow can indicate an issue, prompting immediate corrective action.

- Detect any abnormal changes in flow rates, alerting operators to potential leaks or backflow situations. This enhances overall safety in operations involving combustible gases.

- It protect reverse flow from CO gas holder to LD convertor to avoid accident

Benefits:

- High Accuracy and Repeatability

Ultrasonic flow meters provide high-precision flow measurement, essential for gas balancing and energy recovery.

- Wide Flow Range

These meters can handle a wide range of flow rates, from very low to high velocities, making them suitable for fluctuating LD gas flows.

- No Pressure Drop

Unlike mechanical meters, ultrasonic flow meters do not introduce any pressure drop, maintaining the efficiency of the process and preventing backpressure issues.

- Maintenance-Free Operation

Since there are no moving parts, ultrasonic flow meters require minimal maintenance, ensuring long-term reliability and reducing operational costs.

- Bidirectional Flow Measurement

Ultrasonic meters can measure flow in both directions, which is useful in scenarios where gas may flow back under certain conditions.

- Suitable for Harsh Environments

Ultrasonic flow meters are designed to operate in high-temperature and high-dust environments typical of steel plants.

Final Thoughts & Attainments:

Using ultrasonic flow meters for LD gas flow measurement enhances plant safety, improves energy efficiency, reduces emissions, and ensures compliance with regulatory standards. These meters are highly reliable, low-maintenance, and provide precise measurement even under harsh conditions, making them an ideal choice for modern steel plants.